From the instruments used to the advancement of mining innovation, manganese mining has developed from crude techniques to a profoundly progressed, innovation based process that permits us to accomplish a significant increase in manganese creation. You would need mining gear that is conservative, cost-viable and solid over the long haul has had a constructive outcome on mining proficiency and creation. One of the best of these advantages is waste and synthetic substances decrease.

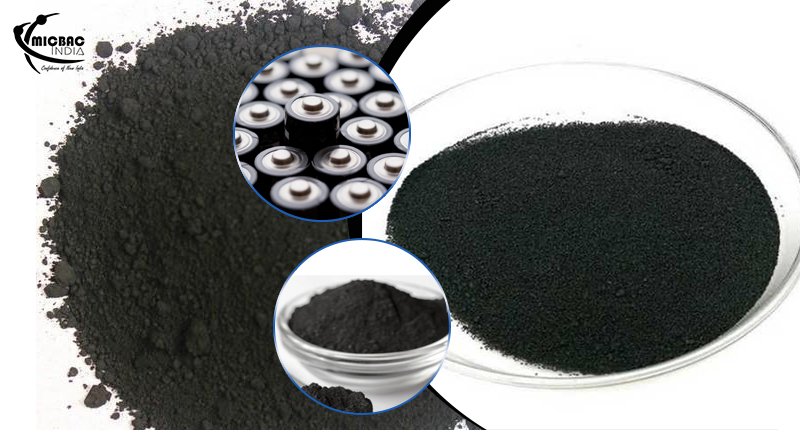

The utilization of manganese goes back to the Stone Age when manganese dioxide made the colors utilized in cavern paintings. Afterward, during Ancient Egyptian and Roman times, manganese aggravates added shading to glass. Compound investigations of manganese during the sixteenth through nineteenth hundreds of years prompted the acknowledgment that the expansion of manganese to press metal based steel made it significantly harder. In this day and age, manganese is often utilized for cathodic shielding in the battery industry.

The Basics of Manganese Mining and Processing

While openness to manganese vapor, residue and mixes ought to be evaded, in safe equations manganese is utilized by most everybody. The way that manganese is a particularly significant metal in our lives clarifies that that mining of it is similarly significant.

What is Manganese used for?

- Gives steel a hard yet malleable quality

- Structures ferromagnetic composites

- Depolarizes dry cell batteries

- De-colorizes glass made green by iron contaminations

- Incredible oxidizing specialist

- Utilized in some composts and for certain grazing creatures

- Found in multivitamin supplements

Where Does Manganese Mining Occur?

Manganese is the fifth most plentiful metal found in the outside layer of the earth. Albeit 80% of manganese resources are found in South Africa, manganese dioxide is also mined in Australia, China, India, Ukraine, Brazil and Gabon. One of the South African mines along the Northern Cape is Tshipi é Ntle, a new open mine pit situated within the Kalahari Manganese Field.

The Manganese Mining Process

In excess of 25 million tons of manganese are mined each year. Most manganese mining happens in open pits. In spite of the fact that there are processes set up to mine manganese knobs in the sea depths, they can’t finish with land-based mining creation. When the metal is mined, it’s moved to a processing plant for electrolytic processing or smelting. Before the improvement of cutting edge innovation mining hardware, freeing manganese from open pit rock beds required significantly more labor and time. But minimal mining gear and its cutting edge innovation permits manganese miners to deliver unmistakably a greater amount of the significant metal than was conceivable even a couple of many years prior.