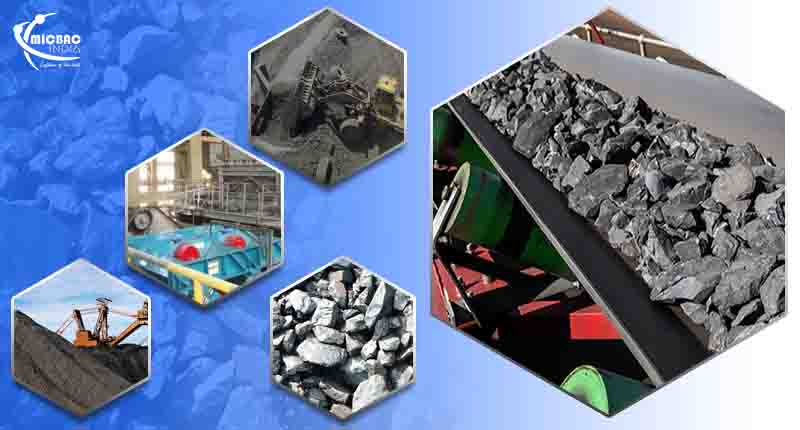

The use of metals is vivid as the human being always wishes to keep the glimmering glow of the same. There was a time when the early man used to push the mine carts. But today, the time has changed. Even in the mining industry the technological advancements has brought dramatic change. The advanced tools are used in the process of mining with the group of technologically savvy people. Also, the miners have a tendency to save the world by utilizing the valuable natural resources in the right way. The extraction of the natural resources is done with enough safety and efficiency.

History of mining

There was a time when the mining played a vital role in the world’s economy. This is right from 1600s which is when the machines were not invented. This was the time when the human being used their own hands to dig and dug. Also, the process involved using of dynamite. The act of mining was done in somewhat haphazard fashion during the early stages. But, there has been a time when a different metal was discovered. This has boosted the hope in the mind of each individual. The gold rush in California in the year 1848 is the greatest example of the same.

Safety and productivity

Of late the mining industry has also become technologically safe and more productive. Also, the computers are shaped that runs the program of extracting the minerals. This becomes quite easy to carry on with the total operation by reducing the cost of hiring the employees. The mining machine and total design of the devices are constructed in such a way that the chances of physical danger will be minimal. The green mining technology is one of the techniques where the environment around the mines will be less affected.

Cutting edge in mining tech

There are mining equipments manufacturing companies that have been providing their clients with state of art technology in providing the best mining equipments available in the market. Mining can take place for several materials. Minerals are one of the important elements that are extracted through the mining tech. The vibratory process as well as sorting machinery fits perfectly. It is also important to have a high performing material processor when there is a requirement of safe and optimum solution of mining. Minerals in different forms are now highly useful to all of us. But, the extraction of the right mineral and that too in perfect form is not possible without the mining. The technological advancement will boost the mining in a right way.

For more information, visit micbacindia.com